TOPICS

Press Release

Piotrek published Joint development program with Australian Govermental Research Organization, CSIRO for Li metal anode of Solid state Electrolyte LIB cell production technology |

||

|

||

| https://www.csiro.au/en/News/News-releases/2019/Piotrek-and-CSIRO-to-make-next-gen-lithium-batteries-for-global-market | ||

| March 4th, 2019 |

Exhibition Report on Battery Japan 2019

Battery Japan 2019 has been held in TOKYO Daiba International Ezhibition Holl (Bigsight) during 27th February to

March 1st, 2019.

We are very pleased to report 60,000 admission and 600 people visiting our booth during those three days to entartain

introducing our ICPm system technology and LIB battery materials for next-generation LIB model.

In particular, cutomers from overseas are intentionally inerested in approaching us and we could be ascertained as a

prospective development works and expected in a realistic technology from commercial and industrial aspects.

Press Release

Succesful development of Ion Conductive binder for ideal closed pack structreelectrode to enhance a stable and efficient conductive network !!

For Next Gen. LIB application, a binder for electrodes of LIB should be altered from non-conductive material to a conductive

binder for any expectation to improve Li + ion transfer inside of LIB cell. This requirements are increasingly expanded to

promote Solid state electrolyte LIB application as one of Next-Gen. LIB model.

Our Iond Conductive binder is to construct stable and uniformly adhesive connections among each particlel of active

materilasl to lead out making uniform conductive networks as well as soft and flexible parts to absorb swelling and shrinking

operation in Charge and Discharge reactions. Details of specific properties shall be refered in other information.

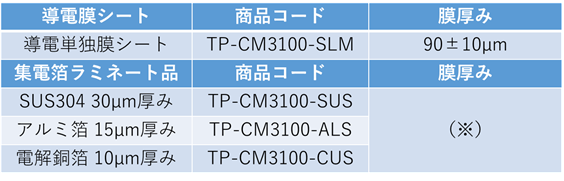

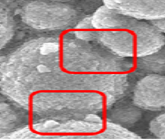

| Base structure of Specific connection parts |

|

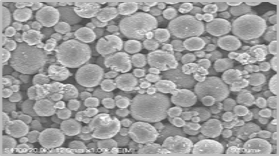

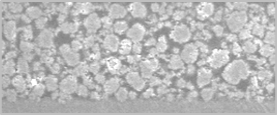

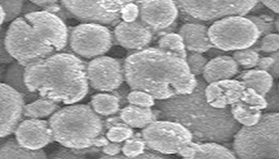

CBC binder recipe -Closed Pack |

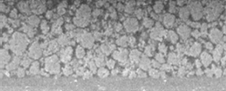

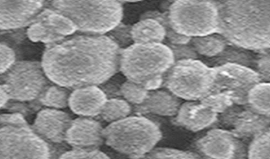

Conventional bionder recipe |

|

Surface photo on SEM |

|

|

Cross Sectoin Photo of SEM |

|

|

Press Densityu 2.8 g/cc |

Press Density 2.6 g/cc |

|

|

|

|

| Keeping shapes by soft and flexible properties | Cracking and broken by hard connection properties |

As shown above, CB binder helps reducing conductive carbon and binder itself to perfm the optimum formulation of each

electrode by increasing an amount of active materials in the formulation.

Please contact us to obtain more information and to try evaluating CB binders in comparison with conventional binders.