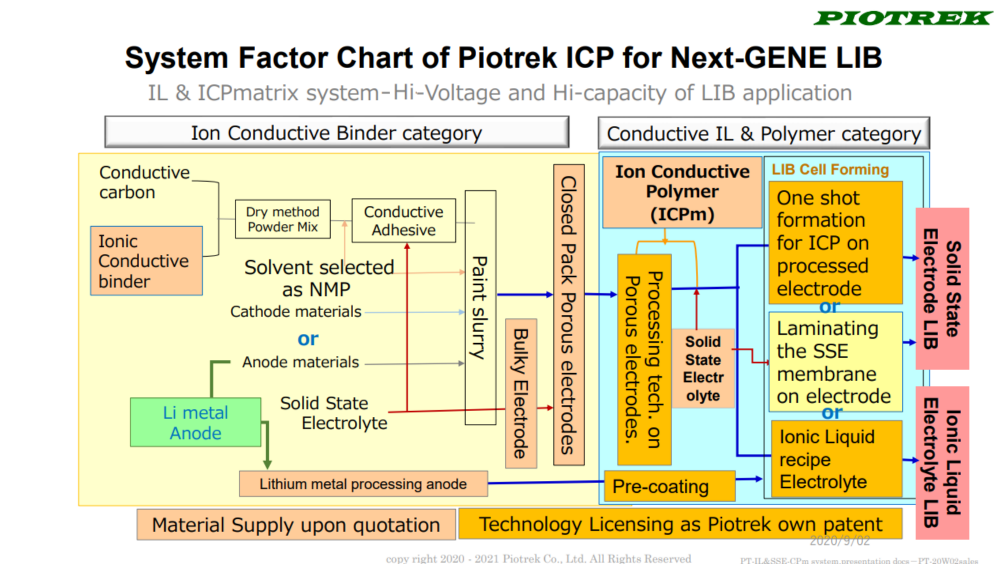

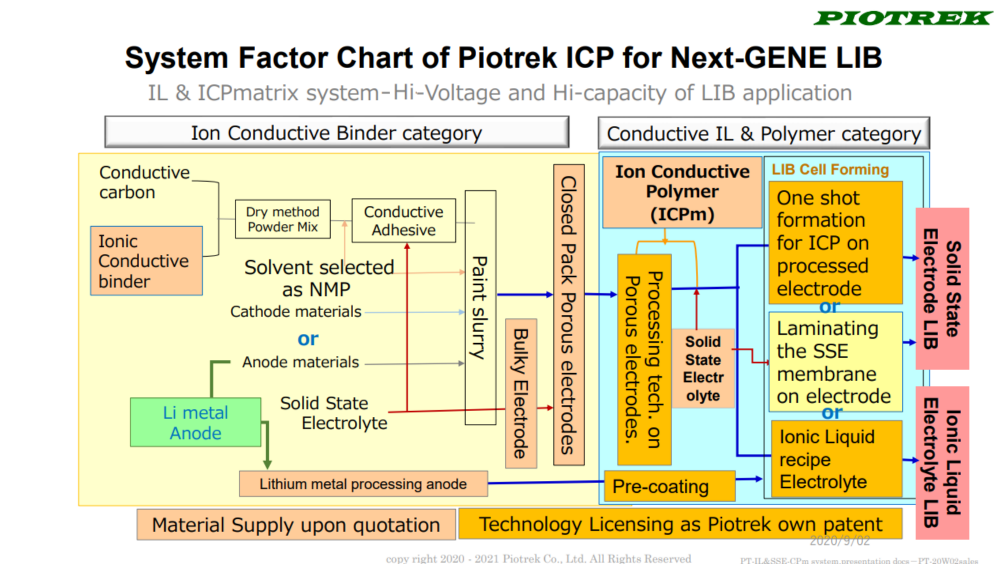

System Technology matrix system technology for Next-GEN battery application

@@@@@Under overall technology for Next|GENE LIB application,@PIOTREK is a developer of ICPm system technology

based on innovative function and high quality material conforming to our accumulated depositing technology in

Practical LIB cell production.

Specific Report for Next-GEN battery applications

Report-1 Hi-Voltage type LIB materials

Report--2 Solid Electrolyte(Polymer)type LIB Materials

Report--3 All SSE(Garnet & NASICON)typeLIB Materials

Report--4 All SSE (Sulfide)LIB Materials

Report--5 CP Hybrid CellI LIB and Buffer Insulator Li metal

Upon your request, each Report brochure is provided for customers' approach to Piotrek technology

Please contact us throughcustomer@piotrek-il.co.jp

To@TOP@@@

@@@@@Under overall technology for Next|GENE LIB application,@PIOTREK is a developer of ICPm system technology

based on innovative function and high quality material conforming to our accumulated depositing technology in

Practical LIB cell production.

Specific Report for Next-GEN battery applications

Report-1 Hi-Voltage type LIB materials

Report--2 Solid Electrolyte(Polymer)type LIB Materials

Report--3 All SSE(Garnet & NASICON)typeLIB Materials

Report--4 All SSE (Sulfide)LIB Materials

Report--5 CP Hybrid CellI LIB and Buffer Insulator Li metal

Upon your request, each Report brochure is provided for customers' approach to Piotrek technology

Please contact us throughcustomer@piotrek-il.co.jp

To@TOP@@@