Success Story

Press Release

Success Report on Innovative Conductive Binder

consisting of ideal conductive network on electrodesII

Material development in adding a conductivity by modified PVdF binder are popular in LIB application, but nobody

could discover a strong enough and elastic conductive binder upon enhancing a dispersibility of conductive agent.

Nowaday, we could achieve this innovative conductive binder having an adhesion part with pedestal form between

active materials. Besides, this adhesion part is of elastic bonding property and also make many spaces surrounding

active material particles to be fulfilled with small or fine active material particles, so called, a close-packed structure

of electrodes. In addition, this mechanism leads out reducing remarkably a volume of binder in use by 40 to 60 wt.% in

comparison with as 100 wt.% of conventional PVdF binder. The performance of each electrodes are almost same initial

chemical electrical properties as that of conventional PVdF in use. But IR drop and higher rating properties are superior

with CBC binder one to conventional binder one.

Innovative function in controllingBoundary and Interfacial resistanceson Particles of Active materials and Solid state electrolyteB @@@@ |

Conventional PVdF Binder |

Ion Conductive Binder |

|

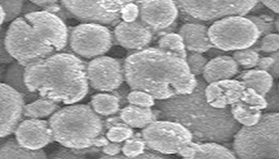

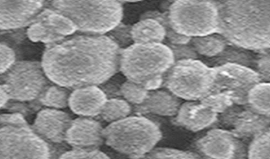

Cross section SEM |

|

|

press density 2.8 g/cc |

press density 2.6 g/cc |

|

| Press Density |  |

|

CB binder assist forming uniform and close-packed filling structure of electrodes to result in reducing the total

volume of binder in each formulation of each active material by means of measuring the proper absorption volume

of NMP solvent toward a conductive agent. This right volume predetermined should be minimum requiring volume

of CB binder to obtain optimum rheology of the coating solution of electrodes. It is the most critical notice in replacing

from conventional PVdF binder to CB binder in each application.

Please try this innovative Conductive binder for your own applications ! !

@Innovative Conductive Binder catalogue

¨conductive binder a4(piotrek181106).pdf

| 2018.08.06 |

@@

@@@@ We opened a booth at the "The 19th International Meeting on Lithium Batteries 2018" held at the Kyoto international @

@@@@ conference center from June 18-22, 2018,   |

| We are promoting to sell various kinds of Battery Materials such as Ionic Liquid(IL), zero solvent IL recipe electrolyte, imide salt as Li-TFSI and Li-FSI,@various Cathode and Anode electrode using conductive binder, Ion Conducive Polymer matrix -solid state electrolyte hybrid membrane sheet and its system technology under our position of "All-round player for LIB". Whenever you are interested in any consultation in the field of materials and technology in LIB application, we welcome your contact to cope with your requirements. This is the contact details. |

@@@@@@ |

| 2017.11.15 |

We have this time joined Batteries 2017 exhibition held in Nice, France during 4th and 6th October, 2017. |

@@@@@@ |

| It was mainly introduced Ion Conductive Polymer(so called ICP) and its derivatives for use in LIB applications. This multi-Function Ion Conductive Polymer is of compositing basically by synthesizing PolyVinylidene DiFluoride (so called PVdF) with Ionic Liquid to enhance ion conductivity property on resin polymer under nonconductive proper The product structure of TREKION CP series is consisted of two backbones in molecule range of resin polymer like PVdF as a main polymer and in molecule rate of synthesizing Ionic Liquid (so called I L) as the term of Ion Conductive Rate ( ICR ) in the range of low to high molecule %with three standard grades. Nowadays, it is available to supply solvent solution grade by dissolving TREKION ICP into N?Methyl-2-pyrolidone (so called NMP), Dimethyl sulfoxide (so called DMSO), Acetonitrile, etc. In the Exhibition Booth No. 647, we introduced the six fields in the LIB business range.@@ |

|

||||||||||||||